by Dee Phanthavong

I Thought I Knew What a Shipping Crate Was!

Prior to working for a crate manufacturer, I thought a crate was just a crate. A crate to me was just a box that people shipped things in. Part of that is true. A shipping crate is for shipping things, but there is a lot of thought and engineering that goes into creating the right crate for our customers’ needs. This begins with our bracket system.

SharkCrates are heavy duty and collapsible wood shipping crates that are economical and easy to use. Instead of using 1×4 and 2×4 framing and cleating like traditional wood crates, we developed a unique bracket system that functions as the crate frame. This invention has given us enormous flexibility in wood crate design, production, functionality, and delivery. An added benefit of the “lumber-free” design is that we are able to preserve precious interior space, thereby decreasing the overall footprint of the crate. We have engineered our crate brackets to specific standards. Our system utilizes 19/32” (sometimes known as 5/8″) panels to secure the crate bottoms, sides, ends, and tops. These panels are thicker than most of our competitors’. It’s important we have a durable product to protect our customers’ products. To me the best part of the design is how simple it is to put together. We purchase so many things that have tons of parts and complicated instructions. Not at SharkCrates! Our design allows for a quick and simple assembly. It makes my job easier and the jobs of everyone who puts them together. We all love a time saving experience!

How Great is a Wood Shipping Crate Without the Right Pallet?

This thought never even crossed my mind before working at SharkCrates. Creating the right pallet for our customers’ needs is extremely important to us. There is a whole lot of thought and questions we ask our customers to help get their needs right. The amount of weight the crate will hold plays a big part in the material we use for the pallet. Whether our customers are using the crates for one-way shipments or anticipate reusing the crates also figure in to how the pallet is designed. We consider if 2-way or 4-way pallet access is needed, and if 2-way access is needed what side to put the opening. We want our customers’ crates to really work for their needs, while keeping in mind how they are going to ship them and LTL carrier requirements and width and height limitations. We know that the people purchasing our crates may not be the same people that use them, so we think about things they may not even know to ask like what a standard dock size is and how tall is a standard LTL truck. We are excited to be our customers’ resource to designing a great crate with a pallet that works!

So How Do You Choose the Right Pallet?

How can you choose the right pallet style? I hope that my explanations of each of our most common offerings help you to pick the right pallet style for your needs.

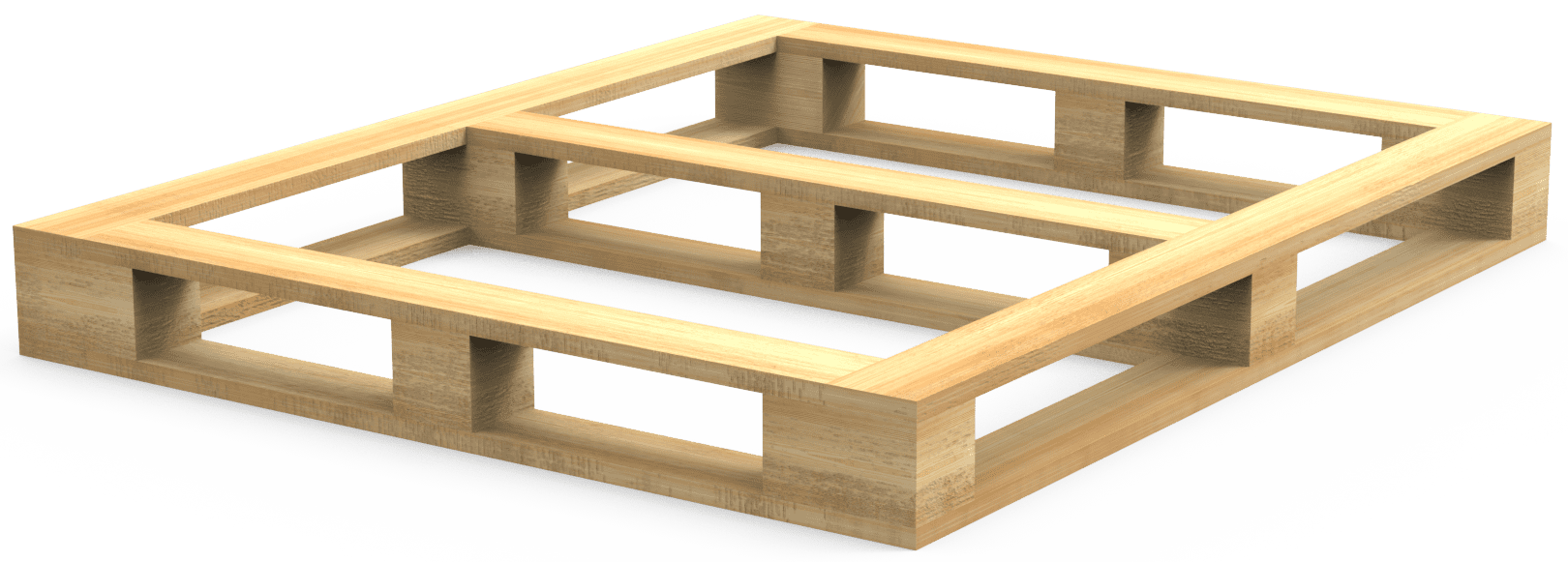

Block Style

The block style pallet is what we use for our stock crates and economical. It has 4-way pallet access and is made from 1×4 lumber and 4×4 blocks. This type of pallet tends to be best for 96” length or less. The larger the crate, the less weight capacity the crate will hold. It is great for one-way shipments but has the potential to be re-usable as well, especially for the smaller sizes. If you are using a pallet jack, this is one style to keep in mind.

Eco Style

The eco style pallet is also an economical option. It has a 2-way pallet access and is made from 1×4 and 1×6 lumber with 2×4 stringers (the middle boards). This pallet type is best for one-way shipments or lighter shipments. Adding some extra top boards can assist with the weight load but heavier shipments would be better suited for our HD pallets. If you are using a pallet jack, this is one style to keep in mind.

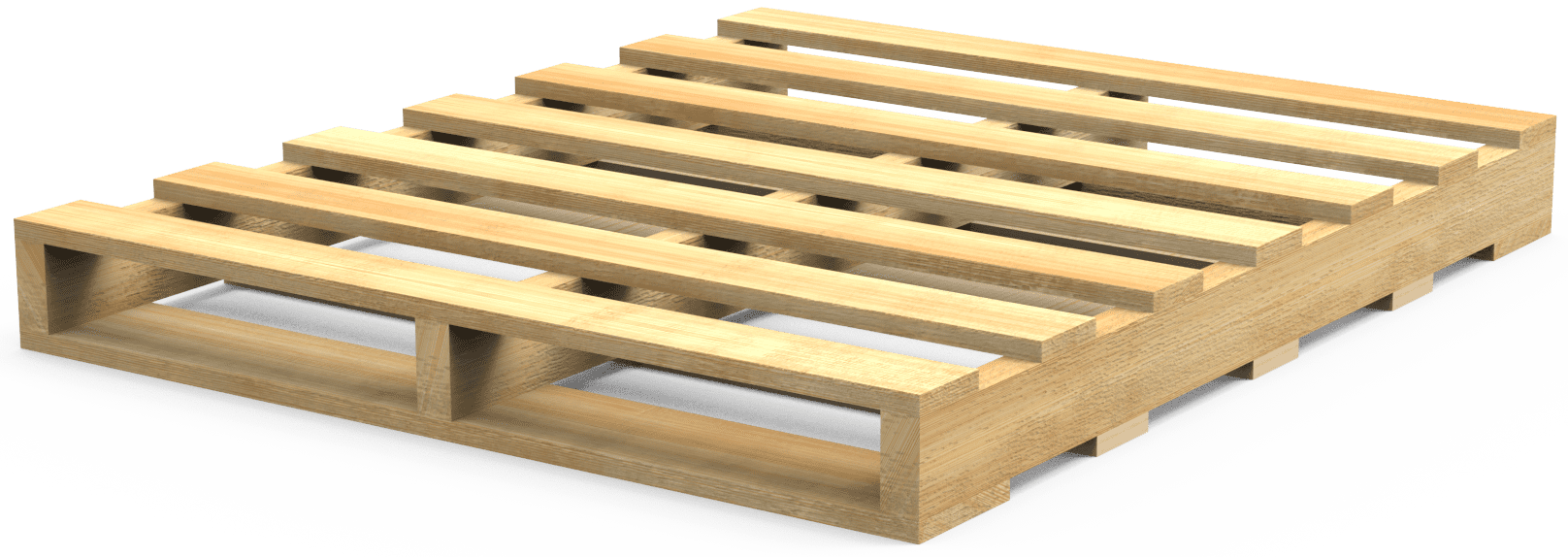

HD Style

The HD style pallet is our heavy-duty option to the Eco style pallet. This pallet is made from 2×4 and 4×4 lumber and is designed to move heavy loads for one-way or returnable shipments. It is also a great option for lagging machinery to the pallet. This style also has 2-way access, like the eco style, so it is important to remember to keep the opening accessible on the side you will need to get it through your dock door and on to a truck. However, you would still be able to “slip skid” these pallets from the other side. Adding additional top boards greatly assists with heavier loads and the ability to lag machinery. This style can also be used with a pallet jack, but with a bit more difficulty having to get the pallet jack over a 2×4 vs a 1×4 board.

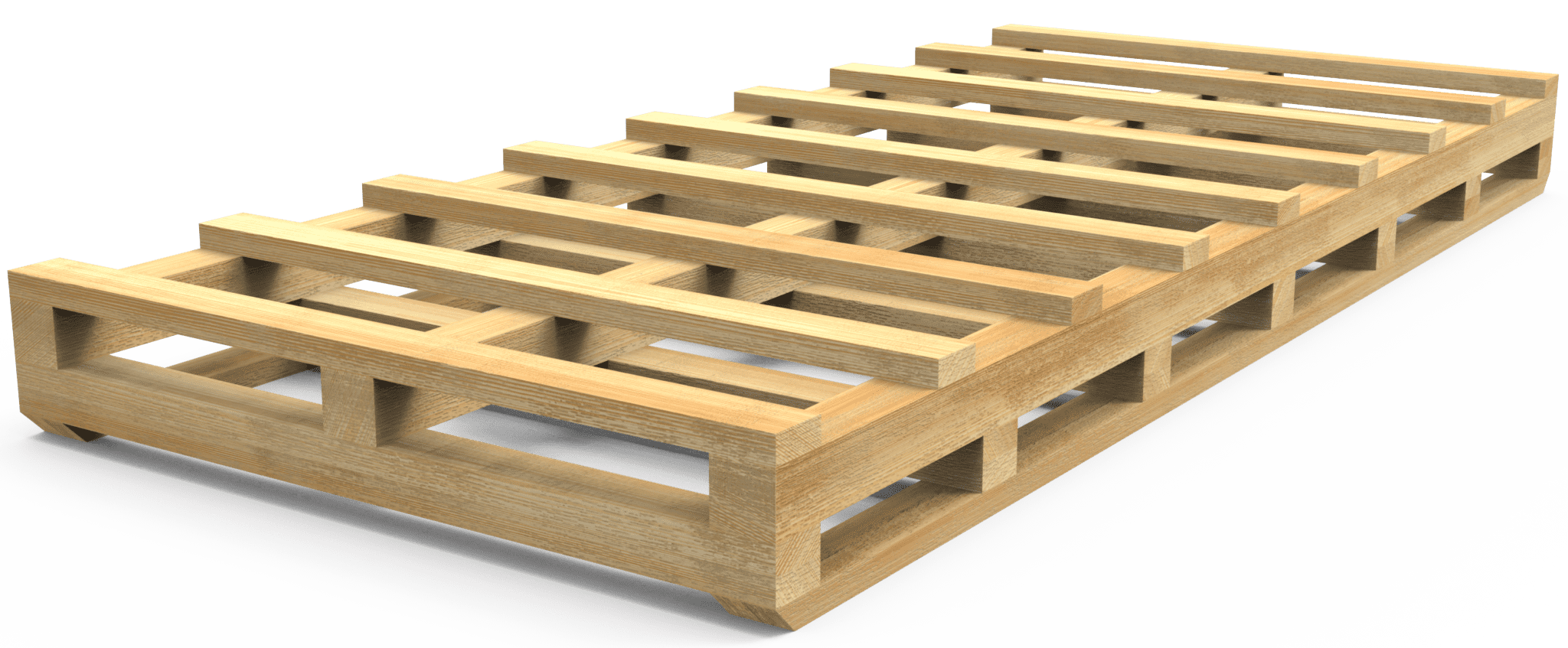

SLHD

The SLHD style pallet is designed primarily for very heavy shipments over 96” long where 4-way forlift access is required. The design is comprised of a solid pallet deck, 4×4 stringers and 2×4 runners with chamfered ends that help minimize damage to the skid when the pallet is inevitably pushed on or pulled off a semi-trailer. We often recommend this pallet style to our trade show customers as it typically offers the most longevity. This style is not pallet jack compatible.